HICOMPELT® composite

The composite material which opens new vistas

Especially in automobile and aircraft construction ever increasing demands in capability and weight reduction challenge the innovative capacity of experienced material specialist. With the composite materials of the HICOMPELT® series Handtmann Elteka presents parts made of a brand new composite material which are produced in a T-RTM process.

What is HICOMPELT®?

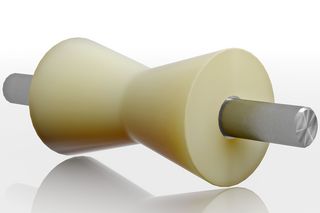

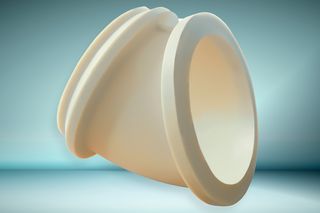

HICOMPELT® is a highly stressable light weight component based on caprolactam and laurinlactam respectively. In combination with

- carbon

- glass fiber or

- a carbon/glass fiber mix

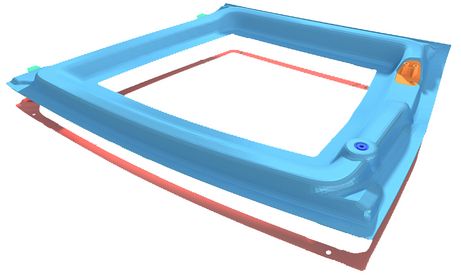

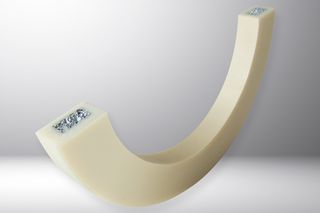

custom-made parts are pressed near net-shape. Thus, light weight structural elements are formed which are, amongst others, employed in automotive and aircraft construction. For example as car tops, seats, mounts or parts of the body.

High fiber content

With regard to the strength-to-weight-rations a high fiber content is important. The specific HICOMPELT® material combination allows for fiber contents of up to 65 %. Thus, HICOMPELT® belongs to the materials with the highest fiber contents on the present composites market.

T-RTM production

With thermoplastic resin transfer molding (T-RTM) Handtmann Elteka offers yet one more production method in addition to Lauramid® casting. This opens up completely new opportunities for your custom-made parts. Due to a specifically engineered mixing unit a caprolactam (PA 6C) or Lauramid® (PA 12C) which is adjusted to the individual demands of the respective application is filled into a molding press. Very short cycle times of +/- 3 minutes support the production of high batch sizes of up to 50.000 units per year with only one tool.

HICOMPELT®: Custom-made composite parts for extreme light weight design.

More information & downloads on HICOMPELT®

Your advantages

- Very short cycle times

- Economic production

- Exceptional strength-to-weight ratios

- Up to 65 % fiber content

- Ease of recycling