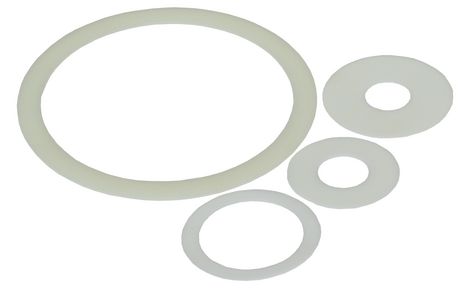

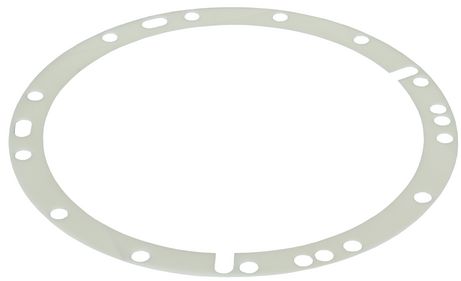

Lauramid® seals: Sealing guaranteed

Seals made of Lauramid® are used in numerous sectors, such as in the food or petrochemicals industry. The key advantages of this material for these applications include the high compression stress and the good recovery values for high and low pressure applications. Furthermore, sealing elements made of this high-tech polyamide prevent gas from diffusing in. The high wear resistance of the Lauramid® high-performance material ensures that the seals have a particularly long service life.

Lauramid® FS: For sensitive fields of application

Our food safe Lauramid® FS cast polyamide version is suitable for fields of application in which the material used must be food safe. Lauramid® FS is tasteless. Seals made of Lauramid® FS are used, for example, in the production of olive oil, where the plastic and the food come into contact with each other for almost 10 minutes during the centrifuge process.

Your advantages

- High compression stress

- Good recovery values for high and low pressure applications (300 bar)

- Temperature resistance up to +140 °C

- Excellent chemical resistance

- No gas diffusion

- Favourable friction coefficient