Lauramid® A with metal combination: Inseparably bonded

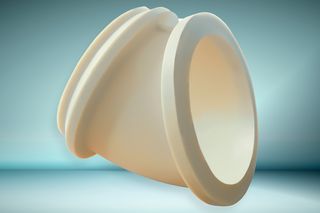

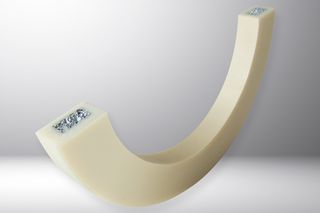

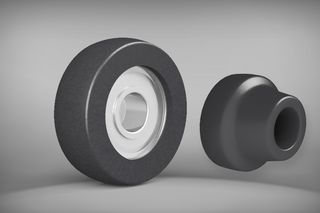

As a low-viscosity melt, the high-performance Lauramid® A polyamide is cast in moulds without pressure. The special casting know-how of the Handtmann Elteka engineers, in combination with the physical properties of the PA 12C modified specifically for this purpose, facilitates the production of plastic components with inseparably encapsulated steel reinforcements or hubs made of, for example, machining steel, C45, S355, V2A, V4A, aluminium or bronze.

Maximum stability ...

With machine components, the directly encapsulated metal core significantly improves stability in the application in comparison to steel elements affixed subsequently. Furthermore, the overall costs of the component are reduced as additional working steps are not required.

... for your component

Whether it be a semi-finished product, finished part or a near net shape component – we at Handtmann Elteka develop and cast the perfect Lauramid® metal compound for your application.

More information & Downloads on Lauramid® A

Your advantages

- High bearing capacity

- Abrasion resistance

- Excellent dimensional stability

- Low rolling resistance

- "Memory effect"