Lauramid® B: For tailor-made plastic components

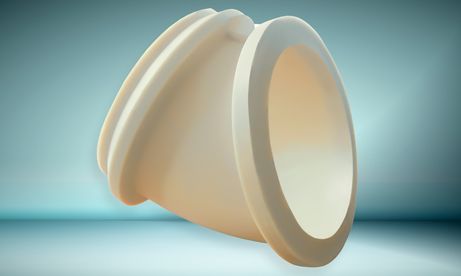

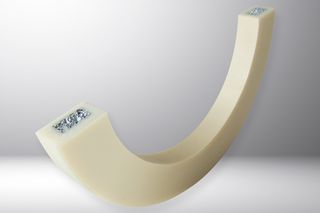

Lauramid® is a polyamide 12C (also known as PA 12G) that is cast in moulds without pressure as a low-viscosity melt. With Lauramid® casting, semi-finished products, finished products and, above all, custom, near net shape components are produced. The material is not extruded, injected or thermoformed as is the case with other plastics but is cast in moulds without pressure.

Extremely wide range of design options

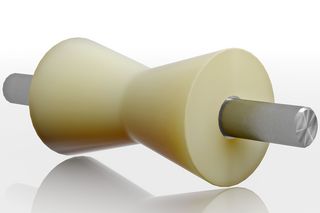

This results in unbeatable advantages for your applications. With Lauramid® casting it is therefore possible to produce much larger components than can be attained with, for example, injection moulding. Inner and outer freeform surfaces, and contours with and without variations in wall thickness can be achieved without any problems with this high-performance polyamide.

Minimum "total cost of ownership"

In terms of mechanical and physical properties, Lauramid® boasts advantages that come into their own especially with complex applications. Due to the longer service life and lower maintenance costs, the total cost of ownership of the components and systems produced from this polyamide is reduced by more than half in some cases.

More information & Downloads on Lauramid® B

Your advantages

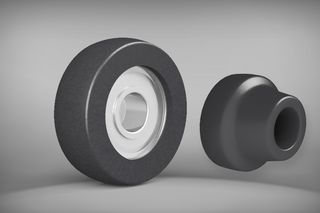

- High bearing capacity

- Abrasion resistance

- Excellent dimensional stability

- Low rolling resistance

- "Memory effect"