New VF 800 D vacuum filler for dairy products

- Division Filling and Portioning Systems

- Posted on 13.03.2018

- All news and dates

New VF 800 D vacuum filler series for dairy products

Market launch at the Anuga FoodTec 2018 in Cologne.

Versatile use. Excellent product quality.

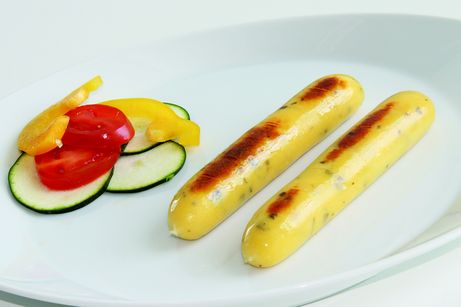

Flexible process modules for dairy applications perfectly customised for the automated production of milk and cheese products all the way through to packaging. This is the new VF 800 D (D = dairy) vacuum filler series from Handtmann. Versatile in use for pasty, chunky, hot or cold dairy products. Filling, portioning, forming, cutting, co-extruding and dosing of goat’s cheese, grilled cheese, yoghurt and quark sticks, spreads, sauces and other products in combination with auxiliary devices – first-class product quality accurate to the gram.

With confirmed compliance with 3-A-Sanitary Standards 23-06

World's first vacuum filling machines (VF 830 D, VF 838 S D, VF 840 D, VF 842 D, VF 848 S D) with confirmed compliance with 3-A-Sanitary Standards 23-06. Specifically, this means strict compliance with excellent hygiene Standards.

Advantages of the new dairy vacuum fillers

- advantages of the new dairy vacuum fillers

- dairy-specific features such as filling level monitoring, closed hopper and an optional integrated UVC module for air degermination

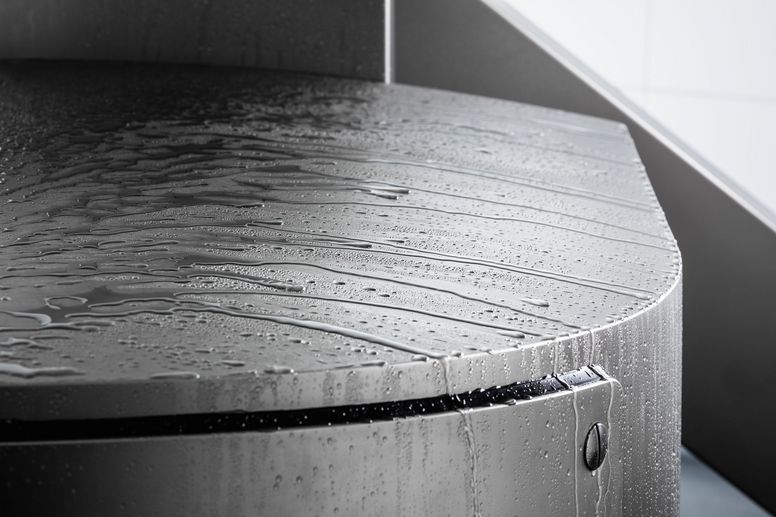

- improved cleaning reliability and less cleaning work thanks to easy to clean external machine surfaces, fewer gaps, edges and dirt traps