The company history from 1873 to 2023. Author: Frank Brunecker

Milestones in the company's history

In 150 years, Handtmann has developed from a small-scale brass foundry in the town centre of Biberach to a globally active technology company in the processing industry with 4,500 employees.

2024

Handtmann acquires the innovative plastics engineering specialist Kegelmann, based in Rodgau-Jügesheim. Kegelmann counts among the pioneers in plastics engineering with genuine expertise in additive manufacturing and the prototyping of injection moulding tools as well as small and special series production.

2023

Markus Handtmann and Valentin Ulrich represent the fifth generation of the Handtmann family to take on management of the Handtmann Group of Companies with headquarters in Biberach an der Riß on 1st April 2023. At the end of June 2023, the current Managing Partner of Handtmann Holding, Thomas Handtmann, will move to the Advisory Board of the family-owned company.

2023

Opening ceremony for the new machining infrastructure in Tianjin: Handtmann Light Metal Foundry (Tianjin) GmbH & Co. KG implements mechanical machining and becomes a full-service provider.

2021

The Handtmann Group of Companies acquires Verbufa B.V., dutch supplier of machinery, devices and components for the food industry. In February 2023, the company is renamed Handtmann Benelux B.V.

2020

The Handtmann Group of Companies acquires Inotec with its locations in Reutlingen, Herzebrock-Clarholz, Hluk (Czech Republic) and Saverne (France). Inotec is a manufacturer of of mixing and grinding technology solutions as well as tying, separating and declipping machines for the food processing sector.

2019

Groundbreaking ceremony for a new factory for aluminium high-pressure die-casting and mechanical machining in Kechnec (Slovakia).

2018

The Handtmann Group of Companies buys Oelmaier Industrieelektronik GmbH & Co. KG in Ochsenhausen and thus lays the foundation for the sixth business division: Handtmann e-solutions.

2018

Arthur Handtmann, President of the Advisory Board of the Handtmann Group of Companies, passes away at the age of 91 on 14th April, 2018.

2017

The new logistics center of Handtmann Maschinenfabrik is put into operation. It comprises a 30-metre high-bay warehouse with 7,500 pallets and a fully automatic small parts warehouse with 65,000 storage bins, in which 85 fully automatic shuttles drive through the alleys to retrieve spare parts and similar items from the bins.

2017

The Handtmann Group of Companies sells Handtmann A-Punkt Automation GmbH and the foreign companies belonging to the division in the USA, Russia and China to the current Managing Director Armin Walther, within the framework of a management buyout.

2016

The second customer forum of Handtmann Maschinenfabrik is opened. With almost 5,000 square meters of floor space, Handtmann now has the largest and most modern training centres for filling and portioning technology in Europe, where customers and Handtmann's worldwide sales representatives can be trained and new processes can be tested and demonstrated live.

Start of construction of a new high-bay warehouse.

2015

Handtmann invests in a new magnesium production facility in Biberach. In addition to aluminium, more cast parts will be produced from magnesium in the future. Magnesium alloys have become interesting materials in the lightweight construction and engine construction sectors, as well as in the automotive construction industry in general, as they boast weight savings, more energy-efficient manufacturing and excellent damping characteristics.

2015

In honour and recognition of his outstanding services to business and for the public welfare, Arthur Handtmann is awarded the Order of Merit of the Federal Republic of Germany – 1st class. Deputy Minister President Dr. Nils Schmid presents the award on behalf of Federal President Joachim Gauck.

2015

Inauguration of a new foundry in China: Since November 2014 the Handtmann Light Metal Foundry (Tianjin) Co., Ltd. has been producing transmission and clutch housings for automobile manufacturers. In just one year, a production hall and administrative building were constructed on a 52,000 square metres plot on the outskirts of the Chinese metropolis of Tianjin.

2013

Albert Handtmann Elteka GmbH & Co. KG relocates from Arthur-Handtmann-Straße in Biberach to the Aspach industrial estate. A production area covering 8,000 square metres and an office building of 1,900 square metres is constructed on a 23,000 square metres plot.

The company has developed into one of the world's leading global manufacturers of engineering plastics. All engineering activities and production, as well as any assembly work for all products, are performed at the headquarters in Biberach.

2013

In Königswalde, Saxony, a group of halls is purchased for the mechanical treatment of aluminium cast parts. In summer 2014, two processing lines for oil pans are installed in their entirety. This solves the problem of a lack of space in Annaberg and all the external warehouses can be vacated.

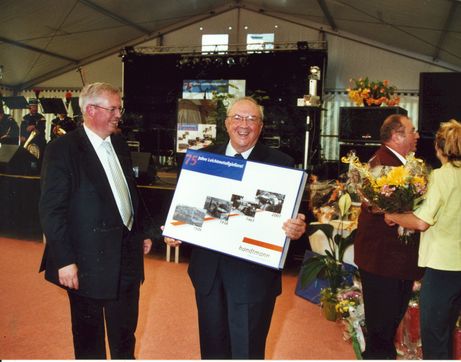

The members of the Handtmann Advisory Board at the inauguration of the Handtmann Maschinenfabrik customer forum.

2010

Inauguration of the newly built Handtmann Forum of Handtmann Maschinenfabrik for customer training purposes. Expansion of production, research and development by 50 percent.

2009

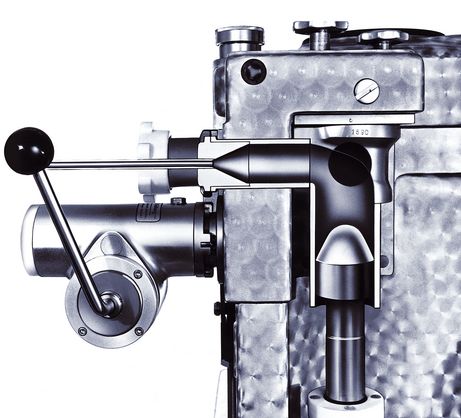

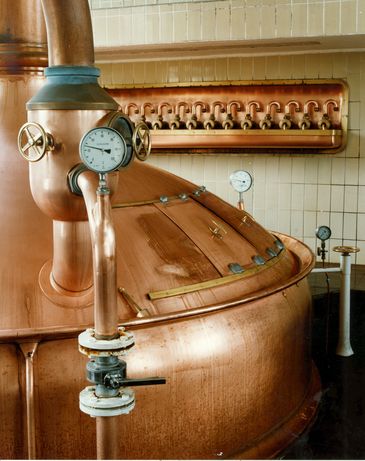

A new production and administrative building for the Armaturenfabrik is constructed in Arthur-Handtmann-Straße in Biberach. Albert Handtmann Armaturenfabrik GmbH & Co. KG is one of the leading suppliers of armatures, valves and process technology for the beverage industry, as well as increasingly for the biotechnology and chemical-pharmaceutical industries.

2009

Handtmann filling and portioning machines are completely dismantled and re-engineered to industrial standards in a new, state-of-the-art assembly plant in Zittau. Handtmann is therefore now able to also offer its legendary Handtmann quality to those international customers who wish to purchase second-hand machines.

2007

The Biberach museum stages the "alles handtmann" special exhibition, covering the Handtmann Group of Companies in the past and the present. 11,000 people visit the elaborate technology presentation at the museum and tour the Handtmann facility.

In 2007, 2,400 people are employed throughout the world. Sales: EUR 496 million.

2005

Establishment of the first foreign company to operate a metal foundry: Handtmann Slovakia s.r.o. The new foundry goes into production in 2009. In 2015, 140 people are employed in Košice.

2004

The Handtmann Maschinenfabrik celebrates its 50th anniversary. Representatives from politics, business, the dealers and agencies, plus customers and employees attend the celebrations.

2003

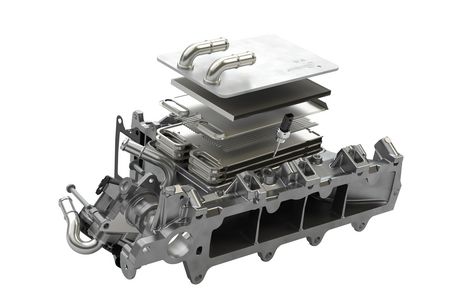

Handtmann Systemtechnik GmbH & Co. KG is established in Biberach. Handtmann is thus responding to the increased demands from the automotive industry. It has become necessary to supply automobile manufacturers components that are ready for installation on the production line, i.e. complete systems, not only cast parts.

2001

Handtmann Leichtmetallgießerei Annaberg GmbH celebrates its 75th anniversary. The staff from Biberach also take part in the evening festivities and the subsequent "open day".

2001

Establishment of the first foreign subsidiary of Handtmann A-Punkt for the sale of machining centres in the USA: Handtmann CNC-Technologies Inc. Other subsidiaries are founded in Russia (2006) and in China (2015).

1999

The expanding Maschinenfabrik in Biberach is moved to the new Aspach industrial zone and fitted with state-of-the-art production equipment.

1998

The 125th company anniversary is celebrated. Minister President Erwin Teufel opens the festivities. Arthur Handtmann steps down as the Managing Director of all companies and becomes Chairman of the newly established Advisory Board. His son Thomas Handtmann takes on the management of the Group of Companies in his place.

In the anniversary year, 1,500 people are employed and sales of DM 498 million are generated.

1997

The turnover exceeds the DM 100 million mark.

1992

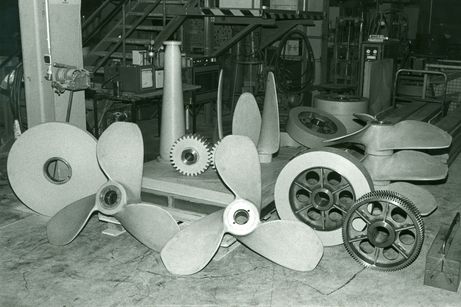

Handtmann acquires Leichtmetallgießerei Annaberg GmbH, which was founded in 1926 by the Zschopauer Motorenwerke DKW. Job security for 100 employees and an investment amount totalling DM 10 million was agreed with the Treuhand state holding company. Handtmann invests more than DM 40 million by 2004.

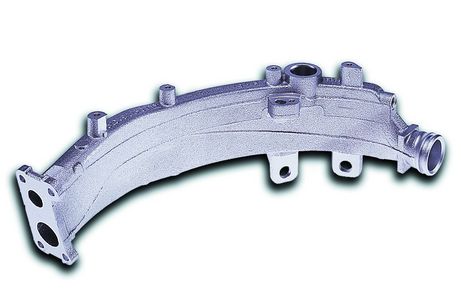

Today, more than 20 state-of-the-art high-pressure die casting machines with closing forces of 420 to 1,300 tonnes are available for the production of aluminium components. High quality casting finishing and CNC processing is integrated into the fully automated production process.

1990

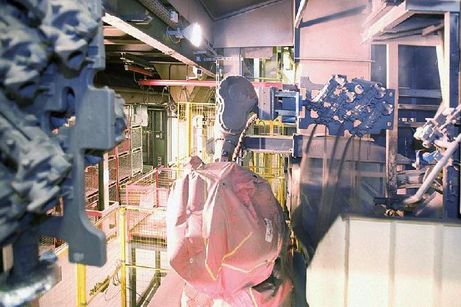

Handtmann begins to use an innovative casting method from the USA – full mould casting or the lost foam casting method. This method is particularly suitable for producing complex cast parts. Five years later, a high volume plant is commissioned.

1989

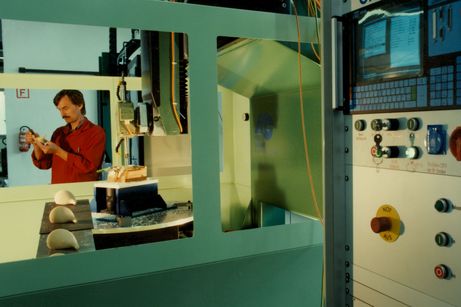

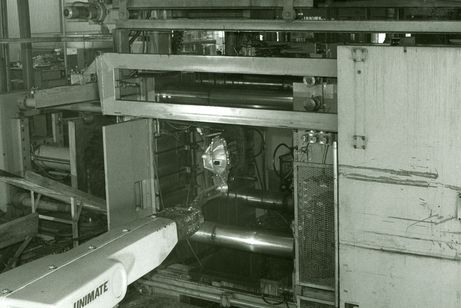

Takeover of A-Punkt Automation in Baienfurt, Germany. Development and production of CNC portal robots for loading and unloading machines. In 1993, the first PBZ profile machining centre is launched. Other series follow: UBZ universal machining centre (1998), Gantry (2003), HBZ AeroCell horizontal machining centre (2007) and Trunnion horizontal machining centre (2012).

1989

Handtmann Maschinenfabrik develops the world’s first microprocessor-controlled vacuum filler VF 80.

1986

The Handtmann Maschinenfabrik establishes the first foreign subsidiary in England for the sale of meat processing machines: Handtmann Ltd. This is followed by additional sales companies in the USA (1990), Italy (1991), Canada (1991), France (1997), Brazil (2000), China (2006), Russia (2014), Mexico (2015), Spain (2019), Brazil (2000), Thailand (2021), Netherlands (2021) and Colombia (2021).

1984

Handtmann Elteka starts production of golf club heads made from Lauramid. Handtmann Sports Int. Corp. is founded in Niceville. The golf club heads are cast in ceramic moulds. Fine machining is carried out in England and the USA. Famous German sports personalities market the products. Willi Hofmann, professional golfer and trainer of Bernhard Langer, is one of the celebrities who helps the marketing activities. In 1996, Handtmann Sports is liquidated due to a lack of contacts in the American golfing world.

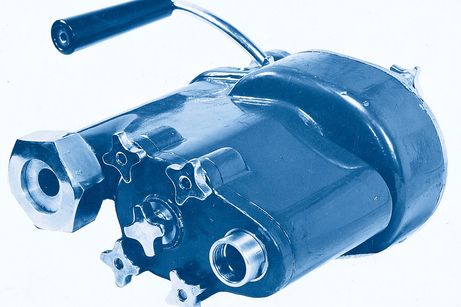

The first major order for the production of cast parts for ABS brake systems for the automotive industry is won.

1982

Thomas Handtmann, Dipl.-Ing. ETH, joins the company management. He represents the fourth generation and guides the family enterprise into the future together with his father Arthur Handtmann. 630 people are employed in the Group of Companies.

1980

Handtmann Maschinenfabrik becomes the world market leader in filling and portioning technology and maintains this position to this day.

1977

At IFFA Handtmann Maschinenfabrik presents the world's first vacuum filler system with an automatic hanging unit.

1969

In 1969, Handtmann launches its first stationary cleaning system for beer tanks. The Armaturenfabrik process engineering activities developed from these cleaning systems.

Handtmann Maschinenfabrik sells the thousandth FA 70 automatic filling machine.

1968

In 1968, Arthur Handtmann enters the plastics development sector with the foundation of Handtmann Elteka. This involves a lactam-based polyamide which is later known under the brand name Lauramid®. It takes 15 years until the very promising new material is ready for production, achieves positive economic results and results in the acquisition of new groups of customers – textile machine manufacturers, paper machine producers, the mountain railway industry etc.

1968

The Handtmann Armaturenfabrik switches from the production of brass fittings to fittings made from stainless steel. 377 people are employed with sales of DM 18 million.

1967

Purchase of company premises on Birkenallee (now called Arthur-Handtmann-Straße), Biberach. In the following years, the various business divisions of the company relocate step-by-step from the Rißstraße to the new company premises.

Handtmann Maschinenfabrik launches the first vacuum filler.

1962

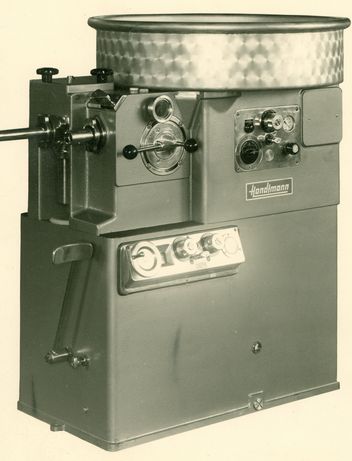

At the IFFA in Munich, Handtmann Maschinenfabrik surprises the experts and sells 152 of its innovative automatic filling machines to customers throughout Europe. 80 people are employed. By then, a series of portioning and linking machines has been created – the Handtmann automatic filling machines in the FA 40 and FA 70 performance versions, as well as six piston filler types, F20 to F70.

1961

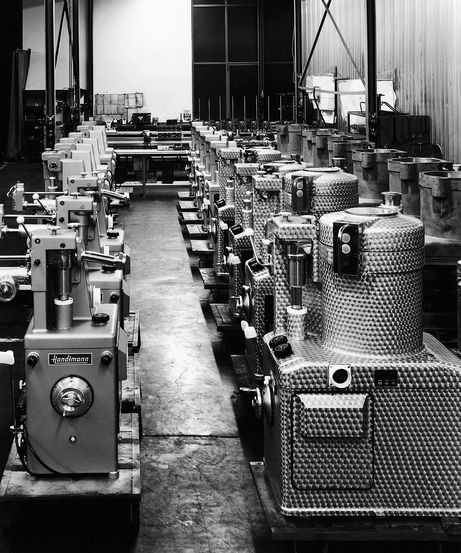

Handtmann starts industrial high-volume aluminium high-pressure die casting. Therefore Handtmann invests in two Fries high-pressure die casting machines with closing forces of 120 and 250 tonnes. Three years later a 400 tonnes machine is added. Initial contact is made with renowned German automotive companies.

1954

Start of gravity die casting. This process is used for complex applications and is suitable for the series production of cast parts weighing up to 20 kilograms.

1954

Establishment of Handtmann Maschinenfabrik.

At the same time as the expansion in the field of light metal casting, Arthur Handtmann decides to set up the company's own mechanical engineering business after he was asked whether he could build a hand-operated sausage filling and portioning machine. It soon becomes clear that only a motorised device can simplify the difficult, monotonous sausage portioning work and bring about real progress.

1953

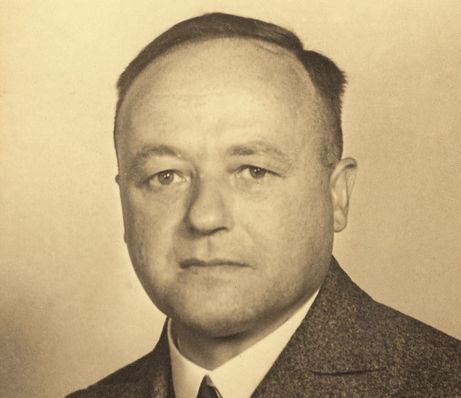

After the death of Adolf Karl Handtmann, Arthur Handtmann became sole owner of the company. Fortunately, Karl Handtmann witnessed the birth and christening of his grandson Thomas Handtmann. Handtmann employs 51 people - more than ever before.

1952

Sales exceed the million mark for the first time.

Arthur Handtmann accepts the aluminium casting of torch parts and air housings for Weißhaupt. In the following years, Weißhaupt turned out to be one of Handtmann's most important business partners.

1946

Aluminium sand casting is added to the production range. In 1960, the metal foundry boasts an automatic sand conditioning unit and six sand cast forming machines. Sand casting production is stopped in 2011.

1945

Arthur Handtmann joins the company as a partner.

Adolf Karl Handtmann (1884-1953)

1944

Adolf Karl Handtmann becomes sole owner of the Albert Handtmann company. In 1947, he employs 18 workers.

1939

At the beginning of the war in 1939, Handtmann employs 35 workers. All the workers are called up, except for five men who are not fit for duty.

1929

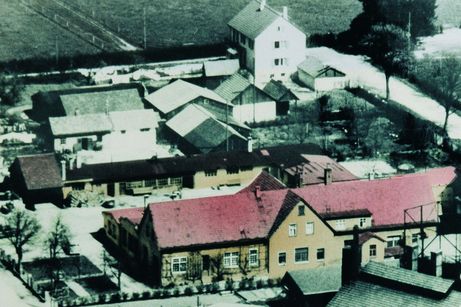

Due to the unpleasant odour in the town centre from the oil heaters in the smelter, the factory is moved out of the town. The new location is Brühlstraße/Fabrikstraße next to the Biberach gasworks. Area of the plot: 6,500 square metres.

Arthur Handtmann in 1941 at the age of 14.

1927

Karl Handtmann's son, Albert Arthur Georg (1927-2018), known by his first name Arthur, is born.

1919

After the death of Christoph Albert Handtmann, his sons Karl Albert Handtmann (1874-1951), known by his first name Albert, and salesman Adolf Karl Handtmann (1884-1953), known by his first name Karl, assume responsibility of the company.

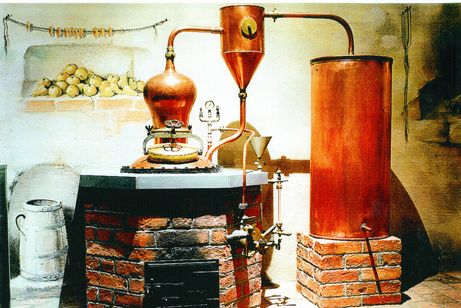

Adolf Karl Handtmann buys machines and modernises. In addition to the company's traditional business with armatures for breweries and distilleries, he starts supplying fitters with taps and annealed cast iron fittings wholesale.

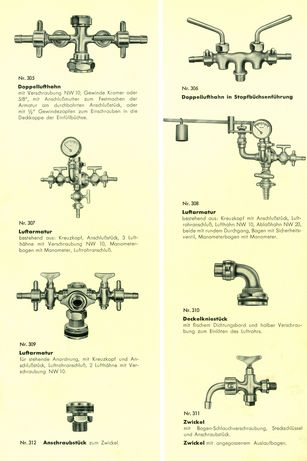

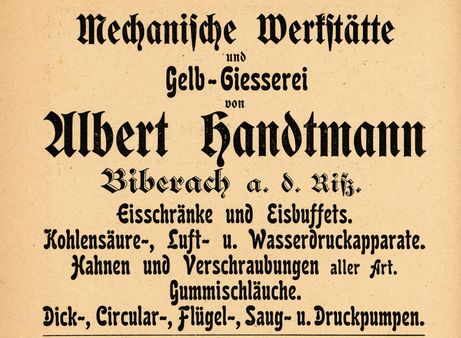

1900

Handtmann is one of the exhibitors and advertisers at the Biberach district trade exhibition. The range is varied: ice cabinets and ice buffets, carbon dioxide, air and water pressure equipment, taps and fittings of all kinds, rubber hoses, thick-, circular-, vane-, suction- and pressure pumps. Barrel engravings are also one of the products of the Handtmann brass foundry. Handtmann supplies breweries and brewing houses via the production of such barrel engravings. This is the early beginning of Handtmann's uninterrupted activity for the beverage industry.

1894

Christoph Albert Handtmann buys his first steam engine with four horsepower for 3,000 marks. The steam engine is the only way out for him to continue his business. Before that, he had used the water power of the "Bachmühle" as a drive for his machine tools. However, with effect from 20 September 1894, the city cancels the lease of the hydropower due to numerous floods in the city.

1873

The bell-foundryman and master mechanic Christoph Albert Handtmann (1845-1918), known by his first name Albert, founds a brass foundry in the historic "Bachmühle" mill on Ehinger-Tor-Platz square in Biberach. The plot has an area of approx. 1,200 square metres.