Vacuum valves

For protection against underpressure in containers or systems

Your benefits

- Safety: Guided valve disc allows reproducible closing and sealing after activation.

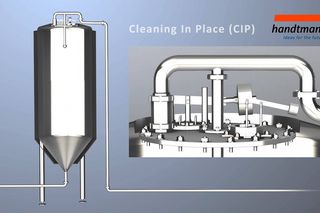

- Time savings: The pneumatic venting allows easy integration of the valve in a fully-automated cleaning cycle (CIP, SIP).

- Flexibility: Horizontal and vertical installation position depending on the operating requirement.

- Design: The division of hosing and flange allows easy replacement of the seal on-site by the customer; full removal of the valve or special tools are not required for this

- Hygienic Design: This ensures safe use especially in hygienically critical processes, e.g. in the food, beverage and pharmaceuticals industry.

Key Facts

1.4404 Stainless st

Materials

25-400 DN

Nominal diameters

3-200 mbar

Set pressure

0-140 °C

Temperature range

Product characteristics

| Sealings | EPDM (FDA) |

|---|---|

| Valves | Spring or weight-loaded |

| Temperature range | According to customer requirements |

| CIP equipment | optional |

| Splash guard variants | optional |

| Valve disc | Guided |

| Aseptic sealing | With accurate compression of the sealing |

Technical documentation

Vacuum valve spring loaded, type 12501/ 12525/ 12537, DN 25 - DN 80

Vaccum valve spring loaded, type 12502/12519, DN 25 - DN 80

Vacuum valve weight loaded, type 12504, flow capacity 14.000 Nm³/h, DN 100 - DN 400

Vacuum valve weight loaded, type 12504, flow capacity 3.600 Nm³/h, DN 100 - DN 200

Vacuum valve weight loaded, type 12504, flow capacity 28.000 Nm³/h, DN 100 - DN 400

Vacuum valve weight loaded, type 12504, flow capacity 4.000 Nm³/h, DN 100 - DN 150

Válvula de vacío cargada por resorte, 12501/ 12525/ 12537, DN 25 - DN 80

Válvula de vacío cargada por peso, 12502/12519, DN 25 - DN 80

Válvula de vacío cargada por peso, 12504, DN 80 - DN 400

Válvula de vacío cargada por peso, 12504, DN 80 - DN 200

Válvula de vacío cargada por peso, 12504, DN 100 - DN 400

Вакуумный клапан, пружинный, 12501/ 12525/ 12537, DN 25 - DN 80

Вакуумный к лапан, с противовесом, 12502/12519, DN 25 - DN 80

Вакуумный клапан, с противовесом, 12504, DN 80 - DN 400

Вакуумный клапан, с противовесом, 12504, DN 80 - DN 200

Вакуумный клапан, с противовесом, 12504, DN 100 - DN 400

![[Translate to English:] Domdeckel [Translate to English:] Domdeckel](/fileadmin/_processed_/0/5/csm_handtmann-dome-caps-1_b372df0582.jpg)

![[Translate to English:] Brauindustrie [Translate to English:] Brauindustrie](/fileadmin/_processed_/1/5/csm_handtmann-beer_aac18d18d1.jpg)

![[Translate to English:] Getränkeindustrie [Translate to English:] Getränkeindustrie](/fileadmin/_processed_/d/0/csm_handtmann-drinks1_6b5bc147b6.jpg)

![[Translate to English:] Lebensmittelindustrie [Translate to English:] Lebensmittelindustrie](/fileadmin/_processed_/5/f/csm_handtmann-food_23be86671a.jpg)

![[Translate to English:] Milchindustrie [Translate to English:] Milchindustrie](/fileadmin/_processed_/1/a/csm_handtmann-dairy_221ddc9163.jpg)

![[Translate to English:] Chemieindustrie [Translate to English:] Chemieindustrie](/fileadmin/_processed_/9/6/csm_handtmann-chemical_e88593b125.jpg)