Double-seat valves

For reliable separation of different media

Your benefits

- Hygienic Design: A reduced number of sealings (3+2) and a product space designed to EHEDG meets highest hygiene requirements.

- Simplicity: Thanks to the screw connection of upper and lower part of the double-seat valve, the valve seat position is twist-proof and thus be assembled reproducibly after sealing replacement. Leakage due to incorrect assembly can be ruled out.

- Flexibility: The variable 360° connectivity paired with the multiple housing combinations allows any custom piping design.

- Safety: The one-piece, massive valve housing with balancer is insensitive to pressure surges up to 45 bar.

- Safety: The closed to the outside housing in combination with the flushing chambers prevent any contact of the product with the environment. On the inside of the double-seat valve, the self-draining valve housing with single-seat, leakage chamber and balancer cleaning allow hygienic, no-loss and safe production.

Key Facts

50-150 DN

Nominal diameters

0-10 bar

Operation pressure

5-8 bar

Control air pressure

0-140 °C

Temperature range

Product characteristics

| Materials product tested: 1.4404 | |

|---|---|

| Pressure surge tested up to 45 bar | |

| Materials (outside): 1.4301 | |

| Surface in contact with the product: Ra ≤ 0.8 μm | |

| Surface (outside): Ra ≤ 1.6 μm | |

| Sealing material EPDM (FDA) | |

| Chambered hygienic profile sealings | |

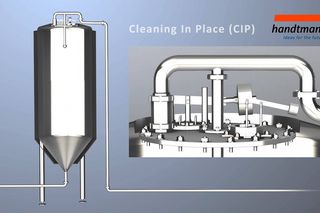

| Individual CIP leakage monitoring | |

| Independent directions of flow from top to bottom or vice versa |

![[Translate to English:] Domdeckel [Translate to English:] Domdeckel](/fileadmin/_processed_/0/5/csm_handtmann-dome-caps-1_b372df0582.jpg)

![[Translate to English:] Brauindustrie [Translate to English:] Brauindustrie](/fileadmin/_processed_/1/5/csm_handtmann-beer_aac18d18d1.jpg)

![[Translate to English:] Getränkeindustrie [Translate to English:] Getränkeindustrie](/fileadmin/_processed_/d/0/csm_handtmann-drinks1_6b5bc147b6.jpg)

![[Translate to English:] Lebensmittelindustrie [Translate to English:] Lebensmittelindustrie](/fileadmin/_processed_/5/f/csm_handtmann-food_23be86671a.jpg)

![[Translate to English:] Milchindustrie [Translate to English:] Milchindustrie](/fileadmin/_processed_/1/a/csm_handtmann-dairy_221ddc9163.jpg)

![[Translate to English:] Chemieindustrie [Translate to English:] Chemieindustrie](/fileadmin/_processed_/9/6/csm_handtmann-chemical_e88593b125.jpg)