| Phone: | +49 7351 45-0 |

| Fax: | +49 7351 45-1599 |

| E-mail: | sales.machines(at)handtmann.de |

| URL: | www.handtmann.de/food |

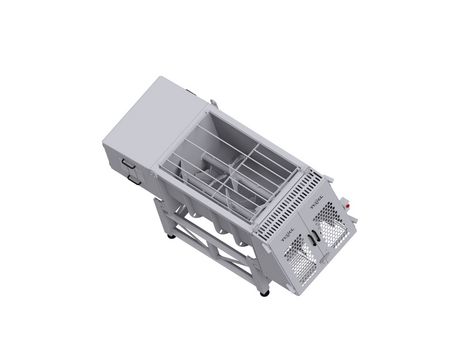

Handtmann Inotec IM mixer

2-shaft mixer for thorough product mixing in food and pet food production.

Handtmann Inotec mixing technology is optimally suited for fast and homogeneous thorough mixing of viscous to highly viscous products in food and pet food production. It is used both in line production and as a stand-alone machine. The different models with paddle shafts, spiral shafts or screw shafts are optimally adapted to the respective application, from meat and meat substitute, to dairy, confectionery and vegan/vegetarian products to baby food and pet food. In every application, medium-scale and industrial producers benefit from fast and optimal mixing with easy emptying via the outlet flaps of the mixers.

Flexible mixing technology in every application

Whether vegan/vegetarian, minced meat, cheese product, baby mash or pet food: Handtmann Inotec mixers provide the optimum shaft configuration for any mixing material. Vertically offset paddle shafts for softer products, parallel paddle shafts for stiffer and viscous products, parallel spiral shafts for highly viscous products or parallel screw shafts for extremely stiff products – the optimum mixing geometry and the variably adjustable mixing from gentle to intensive always ensure an optimum mixing result.

Variety of options further expands the range of applications

The option of heating or cooling products directly (injection) or indirectly (double jacket) allows the processing of both cold and hot products. The addition of liquids and dry substances during operation is possible via additional connections. Load cells provide additional reliability in the process. The texture of the product can be customised through appropriate process steps, vacuum, mixing direction, interval and time as well as pauses. The integrated process control can be individually adapted to a wide range of products. The range of applications for Handtmann Inotec mixing technology is thus comprehensive and universal.

Economical. Compatible. User-friendly.

The mixers are available with a useful volume of 50 to 6,000 litres to accommodate any production volume. They are perfect stand-alone machines but also easy to integrate into existing processing systems. The process control monitors and regulates the user-friendly interface with intuitive input of mixing parameters and central control of the overall process. Emptying is quick and easy via one or two outlet flaps.

TOP FEATURES

50 to 6,000 litres

Usable volume

15.6“ touch control

Control

400 V/50 Hz

Voltage

Top advantages

-

Optimum, consistent mixing results for liquid to highly viscous products due to individually adaptable process steps and mixing from gentle to intensive.

-

Wide range of applications thanks to different mixer configurations, such as paddle, spiral or screw shafts and diverse options, such as heating/cooking, cooling, vacuum and metering.

-

Production reliability through monitoring of the entire process by means of the integrated process control as well as storage of all product and production parameters.

-

High economic efficiency due to a compact, closed system with extremely short mixing times.

-

Excellent hygienic production conditions due to a closed system with hygienic design.

Applications and Product examples

Experience the diversity A suitable solution for every application. Whether meat, dairy, convenience, pet food, fish, confectionary or more.

Our comprehensive service

How to contact us

Do you have any questions or need more information? We look forward to hearing from you.