| Phone: | +49 7351 45-0 |

| Fax: | +49 7351 45-1599 |

| E-mail: | sales.machines(at)handtmann.de |

| URL: | www.handtmann.de/food |

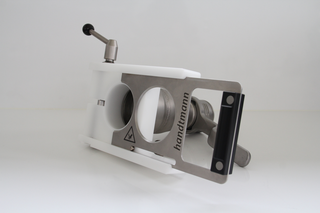

VF 810 vacuum filler

Flexibility for small- and medium-scale producers

The VF 810 vacuum filler of the VF 800 vacuum filler generation is optimally designed for the small-scale and medium-scale producers in the food processing industry and meets a wide range of requirements. It is universally suitable for the gentle yet efficient processing of meat, dough, fillings, as well as vegetarian, vegan, meat substitute, dairy, confectionery and pet food products. The VF 810’s patented vane cell feed system ensures high-precision filling and accurate-to-the-gram portioning of products with pasty to fluid consistency. The optionally attachable lifting device also enables automated and fatigue-free feeding of the vacuum filler.

Universal for an extensive product portfolio

The VF 810 is perfectly suited for the versatile production of a wide range of products. All products are processed with utmost care and portioned accurately to the gram. It can be flexibly combined with auxiliary devices for forming and dosing. Integration in complex line solutions down to the packaging unit is easily possible thanks to its universal interface capability. Numerous options, additional functions and modules extend its versatile and economical utilisation.

Ideal for cooked sausage or the automated production of sausages

The particular strength of the VF 810 is meat and meat substitutes, in particular the production of cooked, fresh and dry sausage products, both as clipping application and in automated sausage production.

The VF 810 ensures sausage production in all types of casing with consistently high output and accurate-to-the-gram quality.

Excellent portioning precision and product quality

The VF 810 guarantees consistently perfect, accurate-to-the-gram portioning precision in all applications, whether using pasty or fluid products. This is due to the vacuum filler’s robust industry-standard design, which thus ensures long-term stable portioning accuracy and at the same time guarantees excellent product quality at a consistently high level.

Optimum hygienic and ergonomic design

The VF 810 has been given a hygienic design in line with the latest guidelines. Automated pre- and interim-cleaning programmes for hopper and feed system and a cleaning quality that can be easily verified guarantee excellent hygiene conditions. Practical advantages in handling and ergonomics perfected to the last detail ensure user-friendliness and highly efficient working.

Top features

up to 1,200

portions/min.

Portioning speed

from 5 to 200,000 g

Portioning range

up to 25 bar

Filling pressure

up to 4,000 kg/h

Filling capacity

Top advantages

-

Consistently high production output of up to 3,000 kg/h or 1,200 portions/minute thanks to the high-precision, high-performance and energy-efficient servo main drive

-

Long-term stable portioning accuracy to the gram in the portioning range of 5 to 200,000 g due to low wear in the vane cell feed system

-

Excellent, reproducible product quality thanks to the gentle feed principle of the vane cell feed system and integrated, digital product quality monitoring

-

Flexibility for a wide variety of applications and products

-

Excellent, high-level hygiene conditions thanks to the latest hygienic design and numerous hygiene-promoting additional options and cleaning programs

-

Outstanding energy efficiency (TÜV-certified) reduces operating costs

-

Modular structure and compatibility with upstream and downstream systems

Product film

Applications and Product examples

Experience the diversity A suitable solution for every application. Whether be it meat, dairy, pet food, fish, confectionary, and more.

Additional equipment and accessories

Documents on the VF 810

How to contact us

Do you have any questions or need more information? We look forward to hearing from you.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/c/csm_handtmann-bockwurst-fresh-sausage-natural-casing-1_b21b8a7442.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/4/csm_handtmann-salads-1_9e69daae3c.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/8/csm_handtmann-maultaschen-3_2c73c5ea71.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/7/csm_handtmann-baked-goods-8_f9ce48f71b.png)