| Phone: | +49 7351 45-0 |

| Fax: | +49 7351 45-1599 |

| E-mail: | sales.machines(at)handtmann.de |

| URL: | www.handtmann.de/food |

VF 800 D VACUUM FILLER FOR DAIRY PRODUCTS

Versatile in use for premium dairy products

Latest vacuum filling technology

The Handtmann VF 800 technology is the state of the art in vacuum filling and portioning technology on the market. It meets highest standards in the field of vacuum filling: Modular. Versatile. Accurate in portioning. Premium quality and more.

Hygienic design in every detail

Smooth-surface design, automatic pre and interim cleaning and a cleaning quality that can be easily verified guarantee excellent hygiene conditions. Reduced cleaning times cut productions costs permanently.

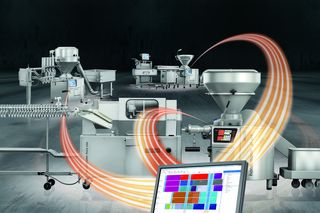

Modular and flexible in complex line solutions

The VF 800 D models are compatible with additional equipment such as Handtmann dosing and forming systems, the Handtmann ConPro system for products in alginate casing, clippers and other upstream or downstream process modules. Synchronisation is carried out simply via monitor control system.

Top features

6.000 - 15.000 kg/h

Filling capacity

25 to 70 bar

Filling pressure

350 litres

Hopper volume

up to 1200 port./min.

Portioning capacity

Top advantages

-

Product-contacting materials and seals meet 3-A Sanitary Standards and FDA (Food and Drug Administration) requirements

-

Maximum surface quality of product-handling components

-

VF 838 S D and VF 848 S D: subsequent filling capacity upgrade via HFM possible.

-

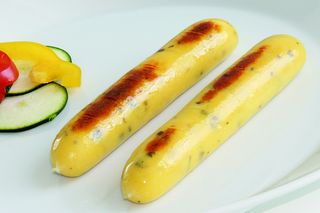

Versatile in use for pasty, chunky, hot or cold dairy products

-

Excellent product quality thanks to the gentle feed principle and portioning accurate to the gram

-

Modular and flexible in line solutions with upstream and downstream systems and devices

-

Outstanding energy efficiency (TÜV-certified)

-

Latest hygienic design at the highest level with confirmed compliance with 3-A Sanitary Standard 17-13

Product films

Applications and product examples - Dairy

Product diversity with classics and trend products: Filling, portioning, linking, dosing, forming, co-extruding and more.

ADDITIONAL EQUIPMENT. ACCESSORIES. OPTIONAL EQUIPMENT.

Variety and efficiency with practical additional equipment, accessories and equipment options

Our comprehensive service

Documents on the VF 830 D

How to contact us

Do you have any questions or need more information? We look forward to hearing from you.